Main technical parameters:

Control the number of wells: single well/multiple wells; (Commonly used 1-20 wells, higher please consult)

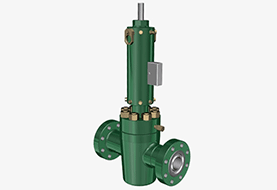

Control valve types: downhole safety valve (SCSSV), surface safety valve (SSV), ESDV, other hydraulic or pneumatic valves; Pressure output range: 0~30000PSI; (For higher pressure, please consult)

Environmental temperature: -40~60 ℃;

Melting temperature of the fusible plug: 160℉ (71 ℃)~281℉ (138 ℃) * optional;

Explosion proof level: not lower than ExdllBT4; Protection level: not less than IP65; Cabinet material: stainless steel (304/316/316L) * optional;

Drive mode: pneumatic/manual/electric/solar.

FEATURES:

• High Safety

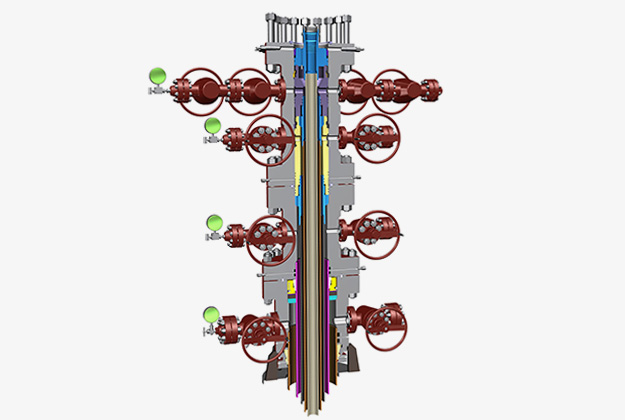

Multiple sensors monitor the wellhead in real-time, triggering the ESD (Emergency Shutdown) function to prevent

accidents such as blowouts and leaks; redundant control ensures operation in case of failures; compliant with ATEX

and IECEx international explosion-proof standards.

• Automation and Intelligence

Capable of integrating with SCADA/DCS systems for remote monitoring and operation, reducing manual intervention;

built-in intelligent diagnostic system can feedback the equipment status in real-time and quickly locate problems,

improving maintenance efficiency; records historical operation data to provide a basis for optimizing production

management and predictive maintenance.

• Strong Environmental Adaptability

Weather-resistant design is suitable for harsh environments such as high temperature, low temperature, high

humidity, and salt spray (e.g., deserts, offshore platforms), with a protection level usually reaching IP65 or above;

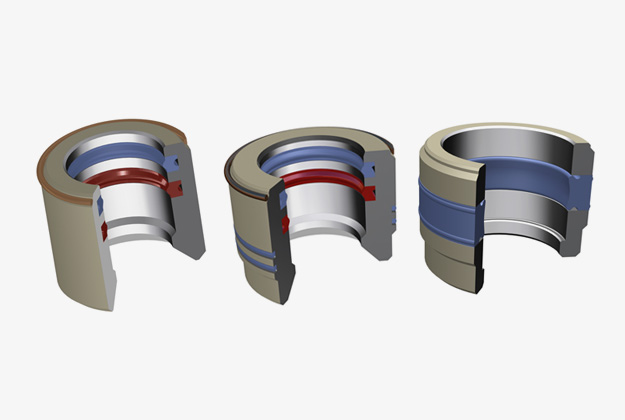

key components are made of stainless steel or with special coatings, extending the equipment lifespan, especially

performing well in corrosive environments containing hydrogen sulfide (H2S).

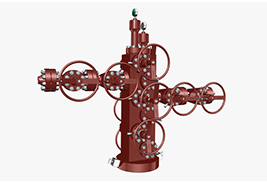

• Modularity and Flexibility

Modular structure allows flexible configuration of functional modules (such as pressure control, chemical injection,

emergency shutdown, etc.) according to wellhead requirements, adapting to different well types (oil wells, gas

wells, injection wells); standardized interface design reduces on-site installation time, and modular components are

convenient for replacement and upgrade.

• Energy-saving and Environmental Protection

Low-power design uses efficient power management technology to reduce energy consumption; precise pressure

control of valves and pipelines reduces the risk of medium leakage, meeting environmental protection regulations.

• Compliance with International Standards

Obtained certifications such as API 6A, ISO 9001, and SIL (Safety Integrity Level) to ensure product reliability and

compliance.