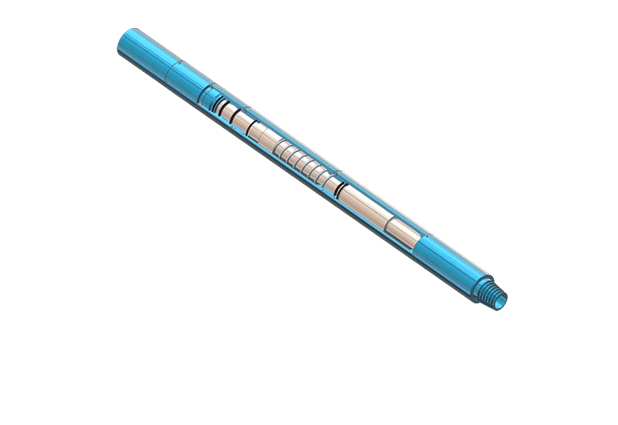

Hydraulic Extended Tool

Extended reach tool creates a smooth fluid pressure pulse that causes vibration in the coiled tubing, which reduces friction between the coiled tubing and the tool string against the wellbore and increase depth and weigh. The motor inside the tool drives the moving valve to realize circular rotation under the liquid drive, and the water flow channel between the moving valve and the fixed valve realizes periodic staggered change, thus generating liquid pulse with a stable frequency. The fluid pulses force the coiled tubing to run in a radial direction to reduce the contact area between the coiled tubing and the wellbore, and finally reduce friction and allow the coiled tubing to run deeper and apply greater weight on bit.