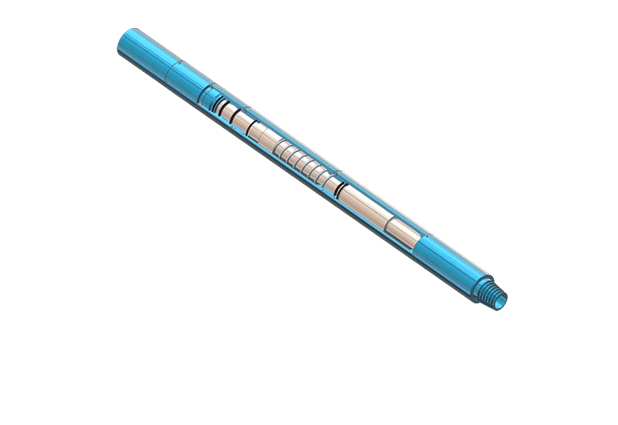

1. Product Introduction

Model GJ-B Retrievable Storm Packers are also used in production stimulation,perforating, gravel packing and testing applications. The hydraulic hold down is below the pressure equalization valve. The tool features a proven three element packing system and a hydraulically controlled balance piston designed to keep the by-pass closed when set.

A hydraulic control balance valve is designed above the hydraulic anchor to ensure that the bypass is closed when the packer is set and can be set securely in any hardness casing.

2. Product Features

Surface controlled combination bypass and equalizing valve.

Balanced piston structure enhances tool stability under pressure

Reliable sealing system that can withstand upper and lower pressure differences during operation.

The automatic J-type device can easily achieve setting and unsetting, and can be set multiple times after running.

Straight pickup of the tubing will first open the bypass valve and equalize pressure, continued pickup will release the packer and automatically engage the packer in the running position for further operations up or down the hole. Guarantee the security of the unsetting operation.

Can withstand higher pressure, 7" and below specifications can withstand up to 70MPa (10000psi) differential pressure.

The recommended operating temperature for conventional gum cover is within 148°C(300°F), cartridges available up to 204°C(400°F)

All Thread connection come standard in API IF thread form

3. Specifications

|

Specification

|

|

Casing OD (in)

|

Casing Wt (lbs/ft)

|

Setting Range

|

Tool OD ( in )

|

Tool ID ( in )

|

Connection Thread

|

|

Min (in)

|

Max (in)

|

|

5

|

15.0-18.0

|

4.25

|

4.408

|

4.13

|

1.75

|

2 3/8" IF

|

|

5 1/2

|

20.0-23.0

|

4.625

|

4.778

|

4.51

|

1.938

|

2 7/8" IF

|

|

5 1/2

|

15.5-20

|

4.778

|

4.95

|

4.64

|

|

5 1/2

|

13.0-15.5

|

4.95

|

5.19

|

4.78

|

|

6 5/8

|

24

|

5.83

|

5.937

|

5.65

|

2.25

|

2 7/8" IF

|

|

7

|

38

|

|

7

|

32.0-35.0

|

5.938

|

6.135

|

5.81

|

|

7

|

26.0-29.0

|

6.136

|

6.276

|

5.97

|

|

7

|

3 1/2" IF

|

|

7

|

20.0-26.0

|

6.276

|

6.456

|

6.07

|

2 7/8" IF

|

|

7

|

17.0-20.0

|

6.456

|

6.578

|

6.27

|

|

7 5/8

|

33.7-39.0

|

6.579

|

6.797

|

6.45

|

|

7 5/8

|

24.0-29.7

|

6.798

|

7.025

|

6.67

|

|

7 5/8

|

20.0-24.0

|

7.025

|

7.125

|

6.81

|

|

8 5/8

|

44.0-49.0

|

7.511

|

7.625

|

7.31

|

2.75

|

3 1/2" IF

|

|

8 5/8

|

32.0-40.0

|

7.725

|

7.921

|

7.53

|

|

8 5/8

|

20.0-28.0

|

8.017

|

8.191

|

7.78

|

|

9 5/8

|

47.0-53.5

|

8.535

|

8.681

|

8.21

|

|

9 5/8

|

40.0-47.0

|

8.681

|

8.835

|

8.44

|

|

9 5/8

|

29.3-36.0

|

8.921

|

9.063

|

8.59

|

|

10 3/4

|

40.5-55.5

|

9.75

|

10.05

|

9.5

|

4 1/2" IF

|

|

10 3/4

|

60.7

|

9.504

|

9.66

|

9.38

|

|

11 3/4

|

60.0-83.0

|

10.192

|

10.772

|

10.06

|

3 1/2" IF

|

|

11 3/4

|

38.0-65.0

|

10.682

|

11.15

|

10.38

|

|

13 3/8

|

48.0-72.0

|

12.347

|

12.715

|

12.13

|

|

13 3/8

|

48.0-72.0

|

12.347

|

12.715

|

12.13

|

4 1/2" IF

|

|

16

|

75.0-102.0

|

14.75

|

15.125

|

14.5

|

3.75

|

4 1/2" IF

|

|

20

|

94.0-133.0

|

18.73

|

19.124

|

18.4

|