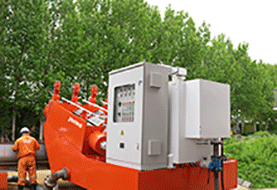

Belt filter press machine

Jerry environmental protection high pressure belt filter press by Jerry environmental protection independent research and development, is a combination of high pressure diaphragm filter press and ordinary belt filter characteristics of high press dehydration equipment. The equipment is mainly used in municipal sewage, food, beverage, chemical, leather, paper making, printing and dyeing, pharmaceutical, coal chemical, mineral processing and other industries sludge reduction. For the sludge with water content of about 80%, the upper and lower two tensioning filter belts entrap the sludge layer, which is s-shaped from a series of regular arrangement of roller cylinders, relying on the tension provided by the plate chain to form the press of sludge, reducing the sludge water content to 60%-65%, to achieve the purpose of deep dehydration.